1. The difference between back-sealed bags and pre-made bags

Before comparing two machines, it’s essential to understand which type of packaging is best suited for your product. You need to analyze whether a FFS machine can create three-side or four-side seal bags and stick bags, or if a pre-made bag machine can accommodate various types like zipper bags, back-seal bags, three-side seal bags, M-shape pouches, gusset pouches, irregular shape pouches, and stand-up pouches with spouts.

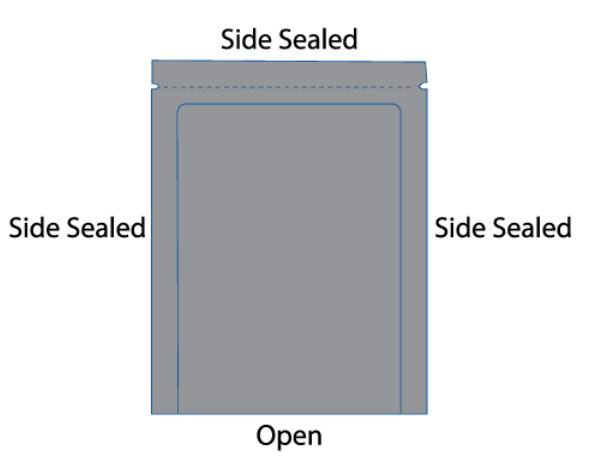

If you’re still unsure about bag choices, let’s compare roll film bags and pre-made bags. A classic example of a roll film bag is the back-seal bag, which has seals at the top and bottom, making it suitable for various products. These bags are usually simple in design, emphasizing practicality for mass production, compact for high-density storage, and cost-effective for large-scale production. They are commonly used for snacks, fruits, and powdered beverages, offering good sealing for long-term storage.

On the other hand, pre-made bags come in many varieties, such as stand-up bags, M bags, and gusset bags. These bags cannot be created on-site with a single machine. Stand-up bags have a flat bottom, allowing them to stand independently, making them great for showcasing snacks, coffee, and dried fruits in retail environments. While they may take up more space, their design attracts consumer attention and enhances brand visibility. Pre-made bags often feature easy-tear openings and resealable designs, improving user experience, but they typically have a higher cost due to their special design and materials, making them suitable for brands focused on market positioning.

2. The difference between VFFS packing machine and pre-made bag packaging machine

Vertical packaging machines complete the entire packaging process by forming bags, filling, and sealing using roll materials. They are suitable for various materials such as granules, powders, and liquids, commonly used in food, cosmetics, and daily chemicals industries for efficient and large-scale production. With strong adaptability to different products, these machines allow quick adjustments of parameters for flexible packaging. They require relatively low initial investment and help save on material and labor costs in the long run, making them ideal for small to medium enterprises. Operation is straightforward, and maintenance is easy, though regular checks of mechanical parts and sensors are necessary. While using pre-made bags may require more setup and adjustments, it offers a wider variety of packaging options.

Pre-made bag packaging machines use already manufactured bags for packaging, completing the process through filling and sealing. They accommodate bags of various shapes and sizes and are often utilized in high-end markets such as specialty foods, pharmaceuticals, and personal care products, especially for bags needing intricate shapes or high-quality printing. Although multi-position bag packing machines are less flexible compared to vertical machines, they perform excellently for specific sizes and shapes. The initial investment is higher, and the cost of pre-made bags is generally greater, catering to brands seeking high quality and unique packaging effects. More setup and adjustments are required upfront, but these machines can achieve high-quality printing and complex designs, enhancing product market appeal and brand value.

3. Vertical Packing Machine Case Study

A classic packaging case comes from a customer in Southeast Asia who needed a customized milk powder packaging machine. We provided a solution using a small vertical machine to package 2-200g of milk powder in three-side sealed bags. This machine produces bags with lengths from 30-200mm and widths from 40-140mm, utilizing PET and Poly roll films. The design includes an easy-open feature for consumer convenience. This solution perfectly matched the client’s expectations, allowing for low-cost, high-volume production of aesthetically pleasing and well-sealed milk powder packages.

4. Doypack Packaging Machine Case Study

Another customer from Europe also sought to package powder, opting for a pre-made bag packaging machine. They desired their product to be in beautifully printed, colorful bags. We recommended a small pre-made bag packaging machine that automatically opens the bags, fills them with material, and seals them. This machine operates at speeds of 20-55 bags per minute, depending on the product and bag weight. For clients focused on brand presentation, this is an excellent choice.

5.Conclusion

In summary, both vertical machines and pre-made bag packaging machines offer unique advantages tailored to different packaging needs. Vertical machines are ideal for versatile applications, efficiently handling a range of materials like powders and liquids in customizable three-side sealed bags. They allow for low-cost, high-volume production with features that enhance user convenience. On the other hand, pre-made bag machines cater to clients seeking high-quality, visually appealing packaging, suitable for products that emphasize brand presentation. These machines streamline the filling and sealing process with beautifully printed bags, making them an excellent choice for premium products. Ultimately, the choice between the two depends on specific product requirements, production goals, and branding strategies.