Introduction

In this article, we will introduce the definition, functions, and applications of bagging machines. We’ll also provide an overview of the disposable products industry and its main offerings, explaining why bagging machines are essential and how they can optimize packaging processes and boost efficiency.

What is a Bagging Machine?

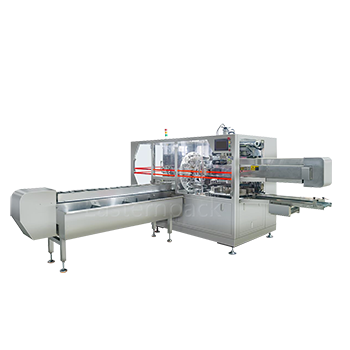

High-speed Flat-push bagging machines are automated packaging systems designed to quickly and efficiently fill and seal bags. They can accommodate various types of packaging bags, such as flat bags and stand-up pouches, and even support vacuum sealing.

These bagging machines operate by opening the bag mouth, inserting the product, and heat-sealing the bag. Automation simplifies packaging operations, while user-friendly touchscreens and programmable logic controllers (PLC) ensure ease of use. Servo motors provide precise bag handling, reducing waste, increasing efficiency, and lowering maintenance costs and operational expenses.

Bagging machines are suitable for packaging a wide range of products, including larger items like snacks, hardware components, and disposable goods. They support various materials such as laminated films, aluminum-coated films, polyethylene/polypropylene composites, and more. Adjustments via the control screen allow for compatibility with different bag sizes and materials.

The versatility and multifunctionality of bagging machines enable businesses to swiftly switch between different bag dimensions, making them ideal for dynamic production environments.

Features of Bagging Machines:

- High Efficiency, Precision, and Stability

- Increased Production Efficiency with Reduced Errors

- User-Friendly and Simple Operation

Overview of the Disposable Products Industry

Key Products:

- Medical Supplies: Disposable gloves, face masks, syringes, sterile dressings, etc.

- Personal Items: Disposable cutlery, wet wipes, tissues, face masks, etc.

Market Demand with increasing global hygiene awareness and the impact of the pandemic, demand for disposable products has surged.

United States:

The U.S. is one of the largest markets for disposable products, particularly in healthcare, food service, and personal care. Common items include disposable tableware, gloves, masks, and wipes. The healthcare sector heavily relies on disposable medical gloves, masks, syringes, and sterile dressings.

Europe:

European countries enforce strict regulations on single-use plastics. Nations like France have enacted laws limiting disposable plastic usage, promoting sustainable and eco-friendly alternatives. Nevertheless, countries like Germany and France maintain high demand for disposable medical supplies (e.g., gloves, masks, syringes), especially in hospitals and clinics.

China:

China’s demand for disposable items is also growing, with a significant spike in personal protective equipment during the pandemic, particularly masks and gloves. The rise of food delivery services has further boosted the need for disposable food packaging materials. Post-pandemic, the demand for travel-related disposable items such as bedsheets, towels, and undergarments has increased significantly due to convenience and practicality.

Other Regions:

India and Japan are also high-demand markets for disposable products. Rising needs in personal care, food packaging, and medical supplies are driving the growth in these regions.

Why Are Bagging Machines Ideal for Disposable Product Packaging?

High Efficiency:

Bagging machines can rapidly package large volumes, handling thousands of bags per hour to meet the fast-growing demand for disposable items.

Flexibility:

They accommodate various shapes and sizes of packaging bags, easily adapting to different specifications of disposable products with minimal adjustments.

Hygiene Standards:

Bagging machines provide high-standard sealing and hygiene for medical and personal products. Parts that contact materials are made of 316 stainless steel, complying with GMP standards.

Automation Benefits:

Reducing manual handling minimizes contamination risks, ensuring product quality and safety.

Versatility:

Capable of processing various materials, such as plastic films, non-woven fabrics, and paper, making them suitable for a wide range of packaging needs.

5. Differences Between Packaging for Medical and Personal Disposable Products

Packaging Requirements:

- Medical Disposable Products: Must meet strict hygiene standards, often requiring sterile packaging or specialized sealing methods.

- Personal Disposable Products: Focus more on convenience, shelf life, and ease of opening.

Packaging Technology Differences:

- Medical Products: Require higher precision, sterile environments, and stringent sealing techniques.

- Personal Products: Emphasize design, convenience, and efficiency for mass production.

Customization Needs:

- Medical Products: Often demand tailored features like moisture-proofing, dust-proofing, and breathability.

- Personal Products: Typically have simpler packaging requirements.

Application of Bagging Machines in Medical Product Packaging

High-speed bagging machines are widely used for packaging disposable medical products such as face masks, protective gowns, IV bags, syringes, sterile dressings, test kits, disinfectant wipes, and pads. Packaging options include individual sealed bags or kits.

These push bagging machines support automated, contactless packaging, sealing, and vacuum functions, ensuring sterile conditions. Automation features allow adjustments for material type, product thickness, and length, while also offering temperature and speed controls. Additional functionalities include automated quantity alarms, batching, and stacking, reducing manual interference and ensuring safe packaging for medical products.

Application of Bagging Machines in Personal Product Packaging

High-speed bagging machines are ideal for packaging personal disposable products such as underwear, towels, bathrobes, bedsheets, socks, travel kits, gloves, razors, and scarves.

These products require individual packaging to prevent dust and contamination, extend shelf life, and ensure hygiene. Independent packaging is preferred in environments like travel, airlines, and hotels due to its convenience and portability.

Given the high consumption rate of personal disposable items, bagging machines with efficient production capabilities meet large-scale production needs while reducing labor and manufacturing costs. Bagging machines can quickly adapt to various bag types and designs, including convenient tear-notch features. They can also be equipped with functions like automated coding and vacuum sealing, and they support biodegradable packaging materials, aligning with environmental trends.

Conclusion

As an automated solution, bagging machines significantly reduce the need for manual labor. Their user-friendly interfaces minimize operator training costs, while sensitive sensors ensure smooth operation. Stainless steel construction meets hygiene standards for medical products, and the controllers enable quick size adjustments to handle diverse bag types. These advantages make bagging machines essential for efficiently and hygienically packaging disposable products.

If you want to know more about bagging machine, please contact us via message, WhatsApp or email!