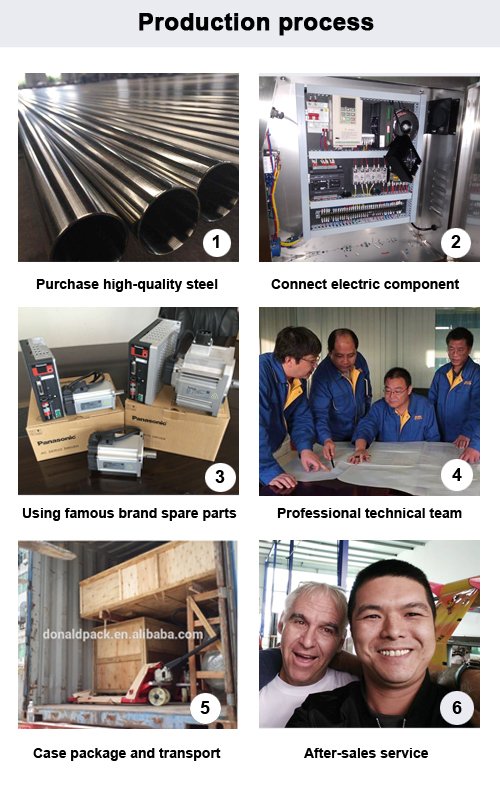

We endeavor to produce packaging machines according to European Standard, we pay more attention to the details design and operation experience degree; We use heart to make our machines safety usage for the customers; And we choose our material very strictly to satisfy customers’ requirements.

This machine can complete the warm paste filling seal press flat exhaust single piece package printing date count and other functions. Can also connect back end 10 pieces bagging pillow machine!

Through PL.C. frequency converter, human-machine interface, encoder, photo-electric and other crganic combined with the realization of intelligent control, the operation is simple and intuitive.

Automatic synchronous feeding, automatic gluing, sealing, rolling and cutting ear strap, ultrasonic welding, product rolling and cutting, synchronous waste col/ection.

It is suitable for packing special bag materials such as warm bag, warm foot pad, warmbag, warm baby and infusion heater. Supporting outer packaging and can form an automatic packaging line.

| Model | D-330 | D-220 | D-550 | D-330S |

| Material Type | Powder | Printed non-woven fabric, needle-punched cotton, stretch cotton | Printed non-woven fabric, needle-punched cotton, | compound material |

| Bag Size | max 330*160mm | Max. width:220mm | W≤520mm,outer diameter of film≤680mm | 330*160mm |

| Capacity | 100-150 bags/min | 80-120 bags/min | 60-100 pieces/min | (3output)120-150bags/min |

| Function | fill,pack,meter,other | |||

| Power | 4.5Kw | 7Kw,380V/220V 50Hz | 380 50/60Hz ,4Kw | 4.5Kw |

| Machine weight | 900kg | 1700kg | 2000kg | 1000kg |

| Machine Dimension | 1900*790*1700mm | 3300*680*1750mm | 4500*1200*1900mm | 1900*790*1700mm |

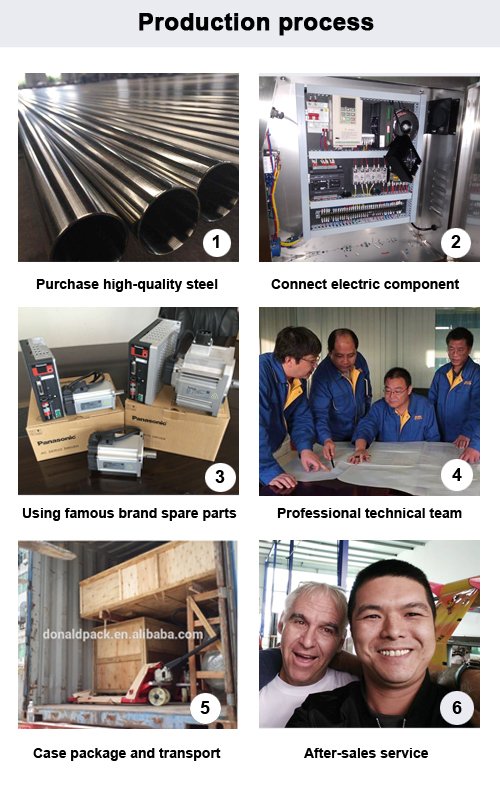

We use adequacy material for producing our machines. The whole set of stainless steel frame for the machine is with thickness of 8mm (other company normally use thickness of 5-6mm only) to make the whole set of machine more strong and steady on the ground. Even during the vibration of running the machine, it will not influence much about the weighing accuracy and film pulling.