In this article,we’ll introduce key features of different tea bag machines. After reading, you’ll have a better understanding of the various types of tea bag packaging machines. Many of these details may not be listed on product pages but could be crucial when choosing your machine. Let’s dive in and learn more about tea bagging machines!

Tea has been a popular beverage worldwide for over a century. With the growth of tea varieties, demand for diverse tea packaging has also increased. Materials such as nylon, polylactic acid (PLA), non-woven fabric, and filter paper composites are now commonly used. Tea varieties have expanded from traditional black and green teas to include a wide range of fruit-infused teas.

Packaging tea is an art in itself, focusing on preserving its flavor. In ancient China, tea was often stored in paper pouches and wooden boxes. Today, tea packaging has evolved for convenience, featuring individually wrapped bags in shapes ranging from traditional rectangular sachets to modern pyramid bags. This article will explore key features of tea bag packaging machines. If you’re set on packaging your tea in bags, keep reading. Other tea packaging methods will be detailed in a future article.

Pyramid tea bags–Pyramid tea bag packing machine

Pyramid tea bags, also known as triangular tea bags, are an innovative way to package tea, designed to enhance the flavor. Many consumers find these tea bags more visually appealing, and sellers often use them for premium loose-leaf teas, herbal blends, and whole-ingredient teas with flower petals or dried fruit. This style allows the ingredients to be visible, helping convey the quality of the tea and enabling a higher price point. The triangular shape also creates more surface area contact with hot water, enriching the tea’s flavor.

Pyramid tea bag machines are usually fully automated and versatile. They can produce both triangular bags and back-sealed bags, with a one-click switch feature to easily change bag styles. Adjusting the bag width on a pyramid tea bag machine is easy, as it requires no additional parts to switch bag formats.

Three side sealed tea bag – Three side sealed tea bag packaging machine

The three-side-sealed tea bag is one of the most common and efficient options, ideal for fine tea powder and broken tea leaves. To make a three-side-seal tea bag, pre-measured tea is filled into the bag, and the open side is sealed to form a fully enclosed package. This is usually done using stable heating elements or ultrasonic sealing. Some manufacturers prefer to further wrap individual tea bags for hygiene and appearance, preventing moisture from entering.

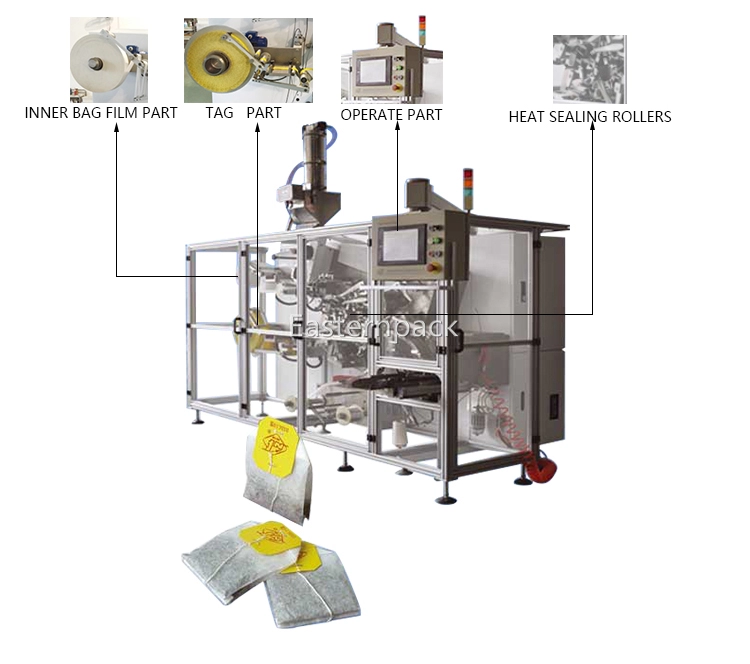

Certain machines can produce both inner and outer bags, automatically placing the sealed tea bag into a separate paper outer bag. The inner bag can be made with or without a string and tag, depending on the preference. However, the bag width and length on a custom tea bag machine are fixed and cannot be adjusted. The temperature settings for each heating component are straightforward to control.

Double chamber tea bag – Double chamber tea bag machine

The double-chamber tea bag design allows tea to be evenly distributed in each chamber, promoting more thorough infusion. Compared to traditional single-chamber tea bags, this style offers a richer flavor and faster brewing, allowing the tea’s taste to develop more fully.

A double-chamber tea bag machine folds and seals filter paper (or other materials) to form two chambers within a single bag, with an option to add a tag and string at the end if needed.

Round tea bags – Round tea bag machine

An uncommon style: round tea bags, typically 20-50mm in size, differ from standard square three-side seal bags and usually do not include a string or tag. For tea bags without tags, strings, or outer bags, a round tea bag packaging machine can produce this style. It features stable bag length cutting via photocell or ultrasonic technology, PID temperature control, a PLC control system, and an easy-to-use touchscreen interface. Some parts are sourced from well-known international brands.

Here’s what you might want to know about tea bag machines:

– Standard tea bag machines can pack a minimum weight of 1g. For weights under 1g, such as 0.7g, a custom weighing device is needed. The tea weighing device has a batch counting feature and can reset to zero easily.

– Precision tea bag machines on the market often use stepper motor control for the outer bag film, ensuring stable bag length cutting. They feature PID temperature control, a PLC system, and touchscreen parameter control.

– Robot Arm: This part grabs the finished inner tea bag from the upper part and moves it to where the outer bag is formed. Since the space between the inner and outer bags is minimal, attaching a string and tag to the inner bag can cause it to get stuck near the outer bag’s opening. In our experience, the ideal inner bag length is 90mm and should not exceed 100mm when using string and tag. Without a string and tag, the bag can turn freely, allowing lengths over 100mm.